Industrial LED Solutions

The Building Blocks of an industrial LED solution

An industrial LED solution consists of several components that autonomously work together to deliver the required performance. To meet specific technical requirements, a LED engine must be equipped with the appropriate hardware and software systems.

1. External Input

External inputs, such as Ethernet (UDP), Industrial Network Protocols (INP), optimized digital contacts (pulse mode), and analog inputs, can be used to control the functionality and parameters of the MaNima system. These inputs provide flexible control over the LED systems depending on the application.

2. MaNima System

The MaNima system manages and monitors the LED engines and fixtures. It is an open, intelligent system that enables users to optimize the performance of their LED engines while ensuring the systems' durability.

Pulse control is critical for most industrial LED applications. With the MaNima system, users have complete control over all settings, including switch-on duration, pulse length, PWM frequency, and strobe characteristics. Thanks to the open architecture of the system, users can configure parameters as needed, ensuring flexibility in tuning LED performance, such as speed and intensity.

In addition to pulse control, the MaNima system allows real-time monitoring of electrical (e.g., current) and physical (e.g., temperature) parameters. This enables users to prevent overheating and optimize performance by ensuring the LED engines operate within safe limits.

In conclusion, the MaNima system allows users to push their LED technology to the limit (in terms of radiation, PPFD, and light intensity) while ensuring long lifespan and sustainable operation.

3. MaNima Cloud

The MaNima Cloud provides users with the ability to remotely monitor and configure their systems, as long as there is an internet connection. The cloud environment also provides access to datalogging of measured parameters via the MaNima Pollux Industry system and offers cloud backups for enhanced data protection.

The MaNima Cloud also provides access to datalogging of measured parameters by the MaNima Pollux Industry and cloud backups.

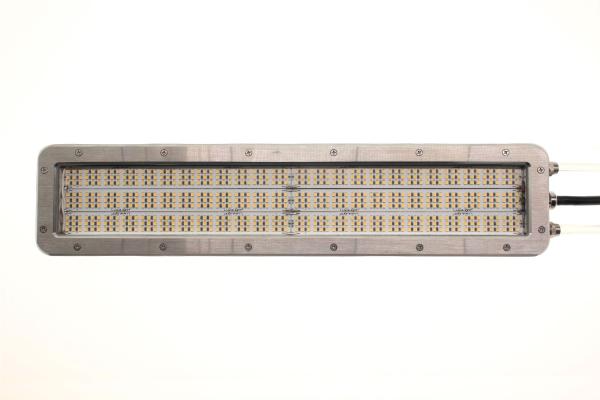

4. LED-Engine

LuxaLight specializes in designing and manufacturing LED engines that seamlessly integrate into industrial systems. With our expertise, we can design components that meet the stringent technical specifications required for various industrial applications.

LED fixtures can be customized to various requirements, such as shape, size, material, wavelength, LED quantity, and desired appearance/lux levels. This also includes properties such as waterproofing (IP), impact resistance (IK), mounting options, and other mechanical requirements for (extreme) environments.

LED fixtures remain custom-made due to the complexity of industrial projects. To address this variety, we have developed modular LED fixtures consisting of standard components that can be configured for any industrial application. This provides a cost-effective solution without compromising on the power or performance of the LED fixtures.

For more information about our Industrial LED Fixtures visit: LuxaLight Industrial LED Fixtures infopage | LuxaLight.

Conclusion

With our extensive in-house expertise, ranging from hardware and software engineering to LED assembly, we are able to design cost-effective LED solutions for the industrial market. With the MaNima system and LuxaLight LED fixtures, we can cover every aspect of the system, from input signals (INP) to the illuminated surface.