Advanced UV-C LED Solutions for Disinfection, 255nm and 265nm

LuxaLight provides both standard and custom LED solutions for disinfection across multiple industries, including medical and food sectors. UV-C LED technology has evolved to the point where it serves as a viable alternative to traditional low-pressure mercury vapor lamps, offering superior energy and cost efficiency over the long term.

Maximum Germicidal Effectiveness

Extensive studies have demonstrated that the peak of maximum germicidal effectiveness occurs at 265nm. UV-C LED chips can be specifically tuned to this wavelength, achieving 100% efficiency at the peak. In contrast, low-pressure UV-C lamps operate at a peak of 253.7nm, with an efficiency of around 80%.

Research further indicates that microorganisms exhibit a specific wavelength at which they are most effectively mutated. This mutation results in the deactivation or destruction of the microorganism. These optimal wavelengths vary for different types of microorganisms, including bacteria, viruses, yeast, and fungi.

Germicidal effectiveness of LuxaLight UV-C fixture compared to Conventional Low Pressure UVC Lamp

Focussing UV-C radiation

Low pressure UVC lamps emit radiation in an 360° direction. Allot of radiation does not reach the target area, resulting in a lower efficiency.

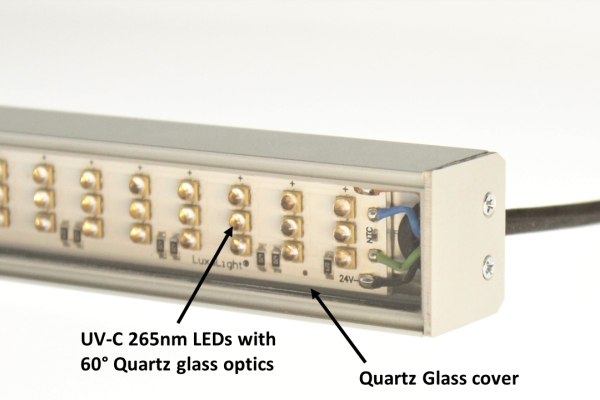

UVC LEDs can be focused into a small cone of radiation. Our standard UVC fixtures are focused into an 60° cone onto the target area with quartz glass optical lenses on the LED chip itself.

Strobing Techniques for UV-C LED Disinfection

UV-C LEDs support strobing, a technique that significantly enhances disinfection efficiency compared to continuous radiation. Strobing not only increases the effectiveness of the disinfection process but also extends the lifespan of the LEDs. This is because strobing generates less heat than continuous radiation. In contrast, strobing with low-pressure UV-C lamps can negatively impact their lifespan, and these lamps also require warm-up and warm-down periods.

Efficiency of Far (200nm - 230nm) and Deep (230nm - 280nm) UV-C LEDs

The germicidal effectiveness curve (shown at the top of the page) indicates that the peak efficacy occurs at 265nm. If the curve were extended down to 200nm, the germicidal effect would be even greater at 200nm than at 265nm. However, 265nm UV-C LEDs are more commonly used for disinfection, as opposed to 200nm LEDs, for the following reasons:

- The cost of Far UV-C LEDs (200nm - 230nm) is significantly higher than Deep UV-C LEDs (230nm - 280nm).

- The energy efficiency of Far UV-C LEDs is substantially lower than that of Deep UV-C LEDs.

These factors make 265nm UV-C LEDs more favorable in terms of price-performance ratio for disinfection applications. The higher efficiency of LEDs in the 255nm - 300nm range contributes to this advantage.

Integrating Intelligence with Industrial LED Applications

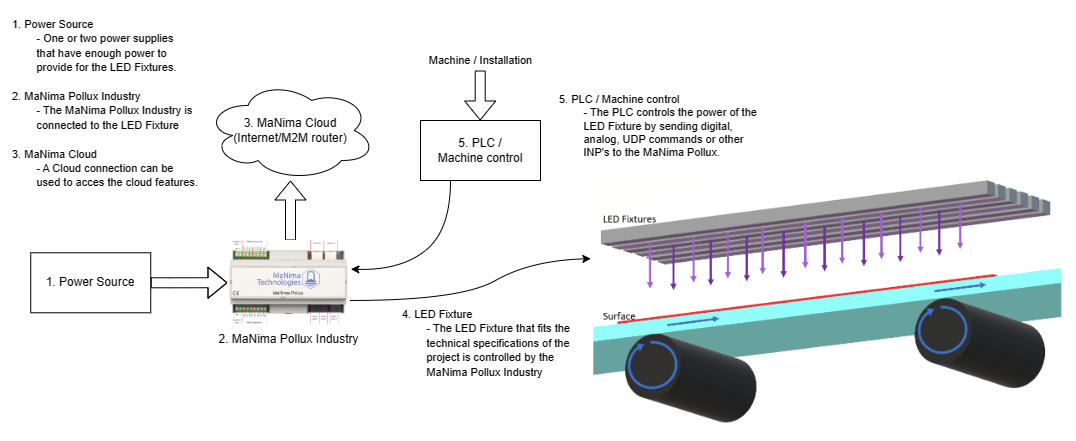

MaNima Technologies provides both hardware and software solutions for UV-C disinfection systems. Through the MaNima Configurator, MaNima Cloud, and UDP commands, parameters such as output intensity, exposure time, and triggers can be easily configured. The MaNima Pollux Industry supports a wide array of inputs and outputs, including digital contacts, Ethernet, and Industrial Network Protocols.

The MaNima Pollux Industry features a pulse mode, enabling the use of 8 speed-optimized digital inputs. These inputs control the PWM outputs, which can pulse at rates ranging from 2µs to 1000ms. Pulse mode is particularly effective for surface disinfection, where pulsating UV-C radiation is applied to treat surfaces.

With the expertise of our engineers, we can seamlessly integrate the developed hardware and software into both existing systems and machines.

For more details on the MaNima System, click here.

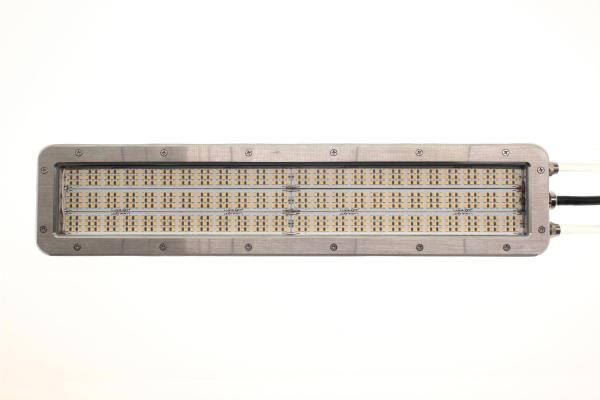

Properties of LuxaLight industrial LED engines

The technical properties of an LED engine are determined on the basis of the application:

- Wavelength

- Heat management

- Radiance per m² (W/m²)

- Opening angle

- Distance from LED engine to object/ surface

- Dimensions object/ surface (maximum)

- (Maximum) mechanical dimensions

- Impact resistance (IK value)

- Waterproofness (IP value)

LuxaLight has the knowledge in the field of soft- and hardware engineering that makes it possible to develop a custom-made LED solution when a standard product is not sufficient.

UV-C LED engines and fixtures in our product portfolio:

Example of a measurement of an UV-C LED engine:

Enclosures

A LED engine should meet mechanical requirements. By determining the right mechanical requirements, a suitable housing can be selected. Mechanical requirements are often taken into account such as:

- Heat management

- Material (e.g. stainless steel, aluminum etc.)

- Waterproofness (IP value)

- Impact resistance (IK value)

- (Maximum) mechanical dimensions

- Mounting options

- Water-cooled stainless steel 316 housing (for applications with high thermal loads, requiring additional cooling to ensure the LED engine’s performance and lifespan)

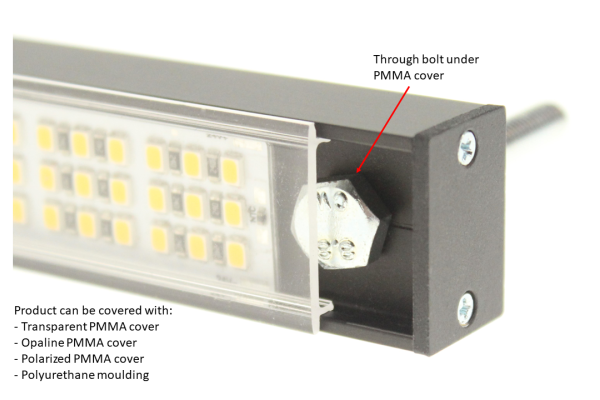

Modular and custom-made LED solutions

For disinfection solutions, we have industrial UV-C LED fixtures in the standard product portfolio. An industrial LED fixture offers the following benefits:

- Variable dimensions possible

- Homogeneous light image by means of lens hood/ LED moulding

- LED moulding compatible

- Various opening angles possible due to optical lenses

- Various mounting options

- Possibility of multiple wavelengths in one fixture

- Economically beneficial due to modular construction

If the standard products do not meet the technical specifications, a custom-made solution is of course also possible.