Curing coatings with UV LED

Irradiation with UV radiation is nowadays a widely used industrial process for curing coatings. Various types of coatings can be cured using this UV technique.

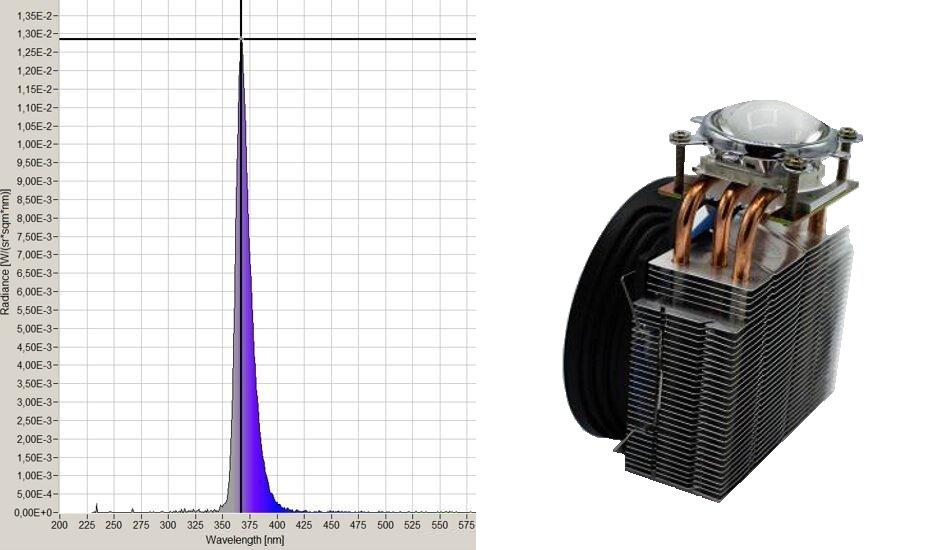

UV curing technology

UV technology uses ultra violet LED light that activates chemical processes. This LED light influences the binding between the molecules. With the help of UV radiation, chemical reaction speeds can be achieved that cannot be achieved with any other technique.

Advantages of curing coatings with UV LED:

- These coatings have a higher mechanical, chemical and thermal resistance.

- The surface is very durable and easy to maintain.

- Curing by means of UV is a drying process in which no solvents are released.

- Material that is cured using UV technology is immediately dry, unlike other drying techniques.

Used components:

- LuxaLight ALU LED-strip 24V UV 255nm Indoor (24 Volt, 30 LEDs, 3535, IP20)

- LuxaLight ALU LED-strip 24V UV 265nm Indoor (24 Volt, 30 LEDs, 3535, IP20)

- LuxaLight Long Life UV LED-strip 395nm Protected (24 Volt, 240 LEDs, 2835, IP64)

- LuxaLight Long Life UV LED-strip 365nm Protected (24 Volt, 240 LEDs, 2835, IP64)

- Round LED 5mm T1¾ 30° 12mW UV 405nm