LED moulding/ LED casting

The casting of LED applications or moulding is increasingly used. The applications are often poured with 2-component silicone or polyurethane.

LED applications

Because LED strips are increasingly used outdoors or in applications with a lot of mechanical stress and tensions, often in combination with an LED strip profile, the casting of LED applications can be an excellent solution. In this way LED can suddenly be suitable for applications for which it could not be used before. LuxaLight, subsidiary of Zirqle LED Solutions, has a specialized department for casting LED applications at its disposal through the cooperation with Zirqle.

Below are some applications where LED casting can offer a suitable solution;

- Underwater lighting, for example as swimming pool lighting and in wellness complexes

- Orientation lighting / line marking, for example in nursing homes

- Maritime industry

- Machine construction, for example in applications that must be resistant to oil and chemicals

- Architectural lighting, such as facade lighting

- Works of art

- Fountains and ponds

- Infrastructure technology, for example in road markings

- Functional lighting for public places

The options for casting are therefore very diverse and one of the biggest advantages is that the positive properties of LED are enhanced.

Advantages of LED casting;

- Better cooling (longer lifespan LEDs)

- Can better withstand mechanical stress (even suitable for paving and floors)

- No condensation in the profile

- Completely waterproof (IP68) while retaining heat dissipation, enabling high-power installations

- UV resistance so does not discolour / yellow

- Very strong and durable IK value 10

- Protects against extreme influences such as chemicals and weather conditions

- Shock and vibration resistant, extends the life of components and the soldering.

LED profiles

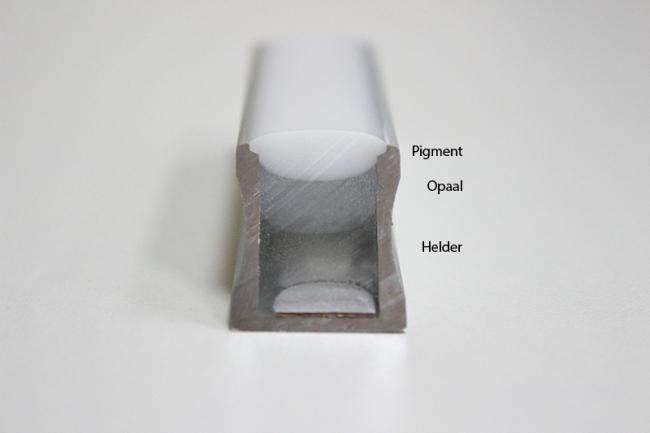

The cast-in LED profiles are available in various degrees of transparency depending on the application, for example from completely bright (hot spots visible), semi (partially) diffuse to completely diffuse (even light image).

Finishing

For the finishing, the polishing of the top layer, various finishing methods are used, such as matt, glossy (high gloss) or a textured finish. Here, too, the requirements set for the assignment are reviewed.

If you would like more information about casting LED strip profiles contact us.