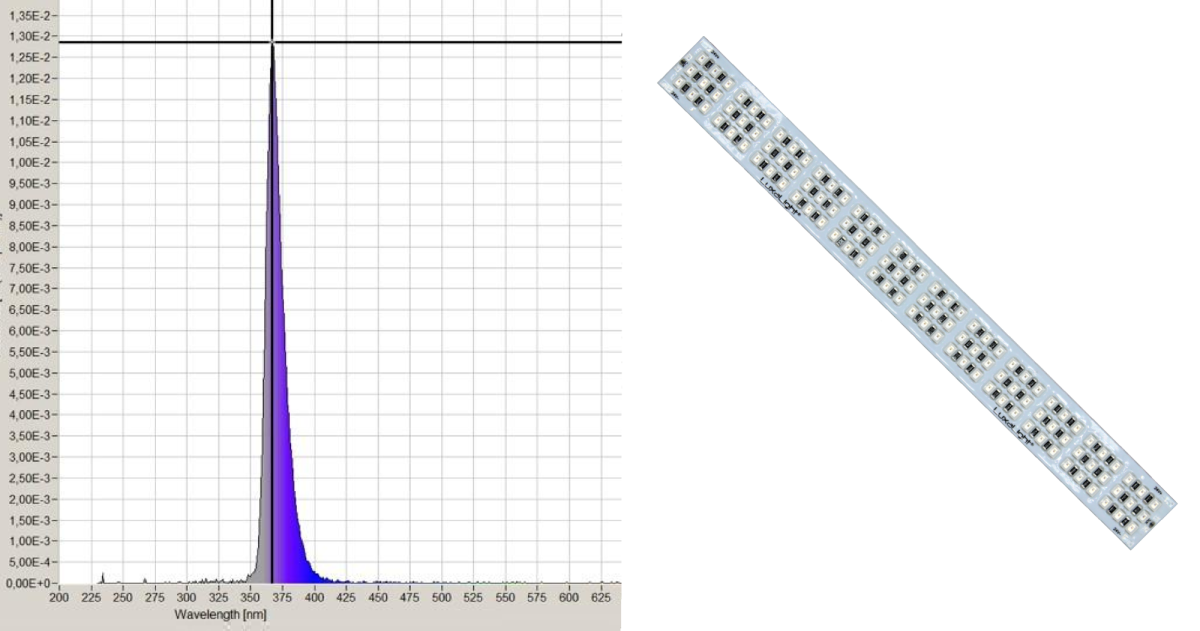

UV 365nm curing LED engines

365nm LED engines are suitable for curing applications including the drying of, for example:

- Adhesives and resins

- Coatings

- Paints and primers

- Fiberglass resin composites

The LED Engines are available separately but can also be supplied as assembled fixtures. All LuxaLight UV-A LED engines are equipped with high efficiency LEDs. By combining the UV 365nm LED engines with a matching heat sink, higher powers and radiation are achievable. These fixtures are always custom made, for more information about our Industrial LED Fixtures click here.

When the fixtures are placed in an environment with high humidity or a large mechanical load, we recommend that these fixtures be cast in.

In order to achieve a higher efficiency and to guarantee a long lifespan, the LuxaLight LED engine is equipped with an NTC. With this NTC it is possible to measure the temperature in real time. More information: LED monitoring

By using the MaNima Pollux Industry in combination with a LED engine, this gives the following benefits:

- Higher return

- Longer life span

- Higher efficiency

- Switching using digital contacts

- Communication through UDP commands (Ethernet)

- Energy saving (fast switching)

- Linking the system through Industrial Network Protocols (INP)

More information: Industrial LED solutions

For more information about curing, visit Zirqle Solutions: Curing UV-A Range - Zirqle Solutions (zirqle-solutions.nl)

Related products:

- MaNima Pollux Industry

- LuxaLight LED Engine 24V 365nm 2835 (24 Volt, 108 LEDs, 2835, IP64)

- LuxaLight Industrial LED Fixture 24V 365nm 24.2x 16mm