UV-A curing solutions, 365nm, 395nm and 405nm

Applications of UV-A 365nm, 395nm, and 405nm Solutions in Various Industries

UV-A radiation technology, with wavelengths of 365nm, 395nm, and 405nm, plays a crucial role in several industrial applications. By utilizing advanced LED technology, companies can enhance the efficiency of their processes, achieve higher radiation intensity, and take advantage of the strobe pulse function. The Manima Pollux driver is an essential device that enables this strobe pulse technology, designed to seamlessly integrate with existing industrial systems. This makes it possible to optimize the speed and precision of UV polymerization and other processes. Below are some key applications:

Adhesives (Polymerization Adhesives)

UV-A LED technology is often used to accelerate the curing of polymerization adhesives. The Manima Pollux driver ensures that strobe pulse technology is applied with high precision, activating the curing process at the exact moment needed. This technology allows adhesives to cure quickly and efficiently without heat development, making it ideal for applications in electronics, medical devices, and the automotive industry.

Resins

UV resins, which react to UV-A light at specific wavelengths, are effectively activated by LED technology. The Manima Pollux driver enables the use of strobe pulse technology, providing controlled curing of resins. In industries like 3D printing and other applications, this accelerates polymerization, leading to higher productivity and improved material properties. The driver allows for perfect synchronization of the UV-A light source with the process, offering greater precision without sacrificing quality.

Coatings

In the coatings industry, the combination of LED-UV technology and the Manima Pollux driver offers immense benefits. The strobe pulse function enables coatings to cure quickly and effectively without the drawbacks of overheating. This technology is particularly important for applications in the graphic arts, automotive, and construction sectors, where speed and reliability are critical. The driver integrates easily with existing systems, providing a flexible solution.

Paints and Primers

UV-sensitive paint and primer systems can be cured more quickly and efficiently using LED-UV radiation controlled by the Manima Pollux driver. The strobe pulse mode allows manufacturers to reduce drying time while maintaining the product's quality and finish. This makes the technology particularly valuable in the automotive and industrial finishing sectors, where rapid production is required.

Glass Fiber Resin Composites

UV-A LED technology accelerates the polymerization of glass fiber resin composites, which is essential for producing strong and lightweight structures. The Manima Pollux driver provides the strobe pulse functionality that further speeds up the curing process, making production more efficient without compromising the strength or durability of the material. This is particularly beneficial for applications in aerospace, automotive, and construction industries.

Photocatalytic Reactor Systems

In photocatalytic reactor systems, the Manima Pollux driver is used to apply strobe pulse technology, increasing the reaction rate of photocatalytic processes. This is critical for air and water purification applications, where photocatalytic reactions need to occur rapidly and efficiently. The strobe pulse functionality allows the UV-A light source to be precisely tuned to meet the process’s needs, resulting in higher efficiency and energy savings.

Photocrosslinkable Hydrogels

Hydrogels that react to UV-A light can be crosslinked quickly and precisely using strobe pulse technology. The Manima Pollux driver allows manufacturers to time the crosslinking process accurately, ensuring the mechanical properties and biocompatibility of hydrogels are optimal for applications in tissue regeneration and controlled drug delivery. This is especially useful in the medical sector, where precision and speed are paramount.

By combining UV-A light at 365nm, 395nm, and 405nm wavelengths with LED technology and the Manima Pollux driver, which enables strobe pulse functionality, companies can significantly benefit from improved production cycles, energy efficiency, and product quality. This driver allows precise control over the strobe pulse, resulting in a more flexible, energy-efficient production process that can be easily integrated into existing industrial systems.

Focusing LEDs compared to not focusing LEDs also has a lot of impact. Below is an image comparing our own LED fixtures, both without optics and with optics.

Strobing Techniques for UV-A LEDs

UV-A LEDs have the capability to strobe, a technique that enhances curing efficiency compared to continuous radiation. Strobing not only improves the effectiveness of the curing process but also helps extend the lifespan of the LEDs. This is because strobing generates less heat compared to continuous operation, preventing the thermal stress that could otherwise shorten LED life. In contrast, strobing with low/medium pressure UVC lamps can negatively affect their lifespan and is not a recommended approach, as it can be destructive to the lamp, which also requires warm-up and warm-down periods.

Integrating Intelligence with Industrial LED Applications

LED interfaces from MaNima Technologies are specifically designed for industrial UV-LED curing applications. With the assistance of our engineering team, the developed hardware and software can be seamlessly integrated into both new and existing systems or machines.

Key parameters such as pulse width, pulse height, strobe characteristics, and triggers can be easily configured using the MaNima Configurator, MaNima Cloud, and UDP commands, providing precise control over curing processes.

The MaNima Pollux Industry supports a wide range of inputs and outputs, including digital contacts, Ethernet, and various Industrial Network Protocols, making it adaptable to a variety of industrial setups.

For more information about the MaNima System click here.

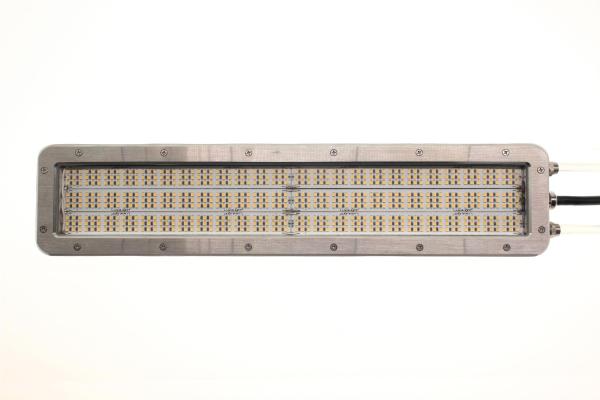

Properties LuxaLight industrial UV-A LED engines

The technical properties of a LED Engine are determined on the basis of the application:

- Wavelength

- Heat management (e.g. embedded NTC, aluminum PCB, etc.)

- Radiation per m² (W/m²)

- Opening angle

- Distance from LED engine to illuminated object/ surface

- m² of the object/ surface to be illuminated

- (Maximum) mechanical dimensions

LuxaLight has the technical knowledge in the field of software and hardware engineering that makes it possible to develop a custom-made LED solution when a standard product is not sufficient.

UV-A LED engines in our product portfolio:

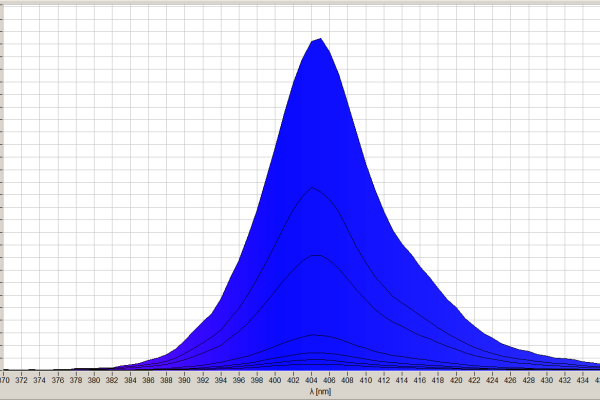

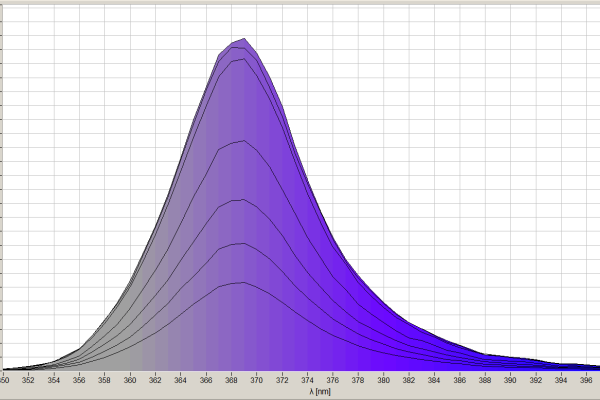

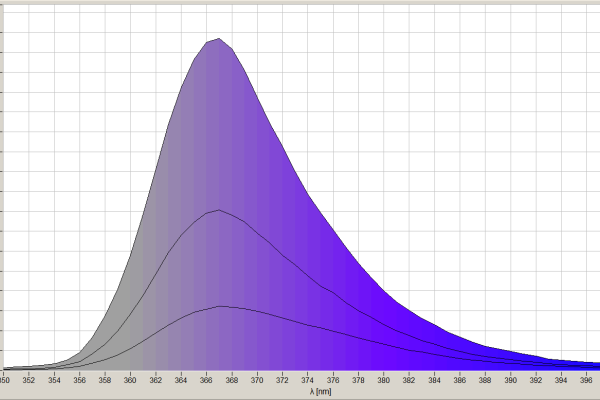

Example of a measurement of a LED engine UV-A:

Enclosures

A LED engine should meet certain mechanical requirements. By selecting the right mechanical requirements, a suitable housing can be selected. Mechanical requirements are often taken into account such as:

- Heat management

- Material (e.g. stainless steel, aluminum etc.)

- Waterproofness (IP value)

- Impact resistance (IK value) (e.g. using quartz glass)

- (Maximum) mechanical dimensions

- Mounting options

- Water-cooled stainless steel 316 housing (for applications with high thermal loads, requiring additional cooling to ensure the LED engine’s performance and lifespan)

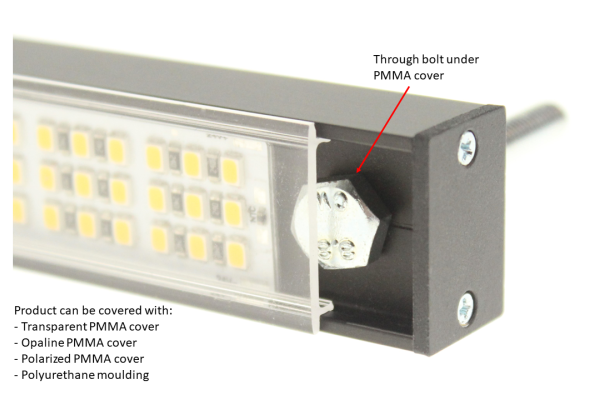

Modular and custom made LED solutions

For LED solutions in the curing industry, we have industrial UV-A LED fixtures in the standard product portfolio. An industrial LED fixture offers the following benefits:

- Variable dimensions possible

- Homogeneous light image by means of lens hood/ LED moulding

- LED moulding compatible

- Various opening angles possible due to optical lenses

- Various mounting options

- Possibility of multiple wavelengths in one fixture

- Economically beneficial due to modular construction

If the standard products do not meet the technical specifications, a custom-made solution is of course also possible.

Casting UV LED engines

In order to meet the technical requirements of the LED application, sometimes a choice has to be made for casting the housing. The composition of the casting resin is determined by the application. Click here for more information about LED moulding.

It is always possible to contact us without any obligation for suitable advice.

Click here for more information about UV curing in industry.